A New Ultra-Thin and Compact Mid Shell® is Here!

This fall, an ultra-thin, compact, and fast-drying Mid Shell® makes its debut. Behind its creation were the challenges of developing an entirely new fabric and finding innovative ways to sew such an extremely thin, lightweight material. We spoke with two Finetrack staff members who led the project to learn about the journey that brought this product to life.

Perfect Partner for “In-Between” Mountain Conditions

Water-resistant, windproof, lightweight, and easy to move in. With its well-balanced performance, the Mid Shell® adapts to a wide range of mountain conditions and shifting temperatures. It provides just enough water resistance to keep you moving through light rain or snow without needing full rainwear, while also delivering excellent breathability and a smooth, non-bulky fit. For many core users and Finetrack staff, it has become a piece they simply cannot part with once they try it.

At the same time, its unique role as “an in-between shell—not quite an outer shell” makes it a niche item in the broader market.

That raised two important questions for us:

- What if we could make it even lighter and more compact, so it could live in your pack as something you only pull out when really needed, like a reliable backup?

- What if we could make it thinner, so the concept of a “Double Shell®” (layering a thin shell under an outer shell) would feel more natural, bringing safety and comfort to a wider range of mountain users?

These were the motivations that led to the development of the new Mid Shell®, the Mu Wrap®.

Pursuing Ultra-Thin Fabric Development

Tanaka (left), from Textile development; Morita (right), from Product development

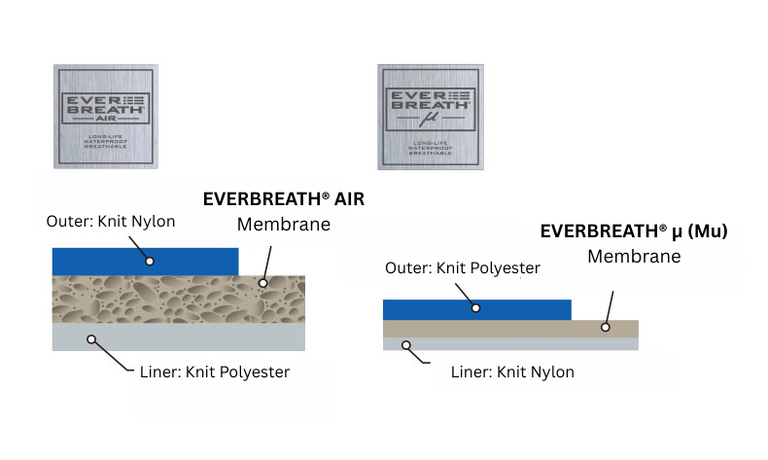

Until now, Finetrack’s waterproof-breathable fabrics have used a microporous membrane, which maintains breathability even when wet.

The drawback of microporous membranes is durability. Because they are full of tiny holes, they need a certain thickness to stay strong. This makes it difficult to push the fabric to be truly thin and lightweight.

To go thinner, the logical answer was to use a non-porous membrane.

But there was a problem. Most non-porous membranes are made of polyurethane, which absorbs water, swells, and dries slowly. Once that happens, breathability drops dramatically. In lab tests, polyurethane may still show high breathability, but in the field it quickly feels stuffy and uncomfortable. And no matter how light a garment is, it’s useless if it doesn’t keep you comfortable on the mountain.

The breakthrough came with a polyester-based non-porous membrane. It works on the same principle as polyurethane but releases absorbed water far more quickly, allowing it to maintain breathability over time.

The membrane we developed is about one-third the thickness of our conventional Everbreath® membrane. By laminating it with a 15-denier polyester knit on the outside and a 7-denier nylon knit on the inside, we succeeded in creating an ultra-thin, lightweight, and compact waterproof-breathable fabric.

We named it Everbreath® μ (Mu).

Microporous Everbreath® Air (left) used in Flow Wrap®, and non-porous Everbreath® μ (right) used in Mu Wrap®

Versatile Shell for a Wide Range of Conditions

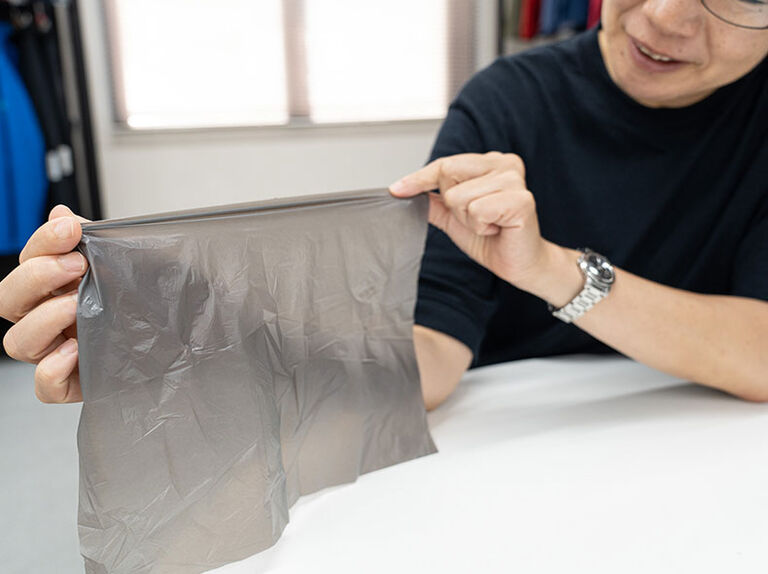

It took five years to bring this fabric to life. The biggest challenge was laminating such ultra-thin materials into a three-layer structure, a success made possible by the advanced textile processing technology found in Japan.

Once the fabric was nearly complete, we created prototypes and put them through field tests with our staff. Because the material is so thin and flexible, using the same sizing as previous Mid Shell® jackets didn’t work. In spring and autumn, when fewer inner layers are worn, the fit felt loose and the fabric flapped in the wind.

To solve this, we fine-tuned the design, narrowing the torso and underarms while still leaving room for thicker mid layers in winter. The result is a well-balanced fit that works comfortably across a wide range of seasons.

Feather-light outer fabric, laminated to the membrane with precision

Everbreath® μ (Mu) Membrane

Design Details, Packability, and Role in the Lineup

To keep the jacket light and compact, we eliminated heavy materials at key points like the hood and cuffs. Instead, we designed them to fit closely and block wind, light rain, and snow without adding bulk. The hood, for example, uses a simple elastic shirring system that gives a snug fit while keeping weight to a minimum.

One of the biggest challenges was sewing the ultra-thin three-layer fabric itself. Because it is both stretchy and delicate, standard stitching often caused problems with balance and durability. After repeated trials with different threads and sewing methods, we finally developed a construction technique that preserves both comfort and strength.

The result is a Mid Shell® that is lighter, more compact, and easier to carry than ever before. Packed down, it becomes so small that it can slip into your pack as a reliable backup layer, ready when you need it most.

Morita showing patterns and product specifications

A simple hood that fits securely using elastic shirring

With the addition of Mu Wrap®, hikers now have two Mid Shell® options. The Flow Wrap® remains the go-to for warmth and durability, while the Mu Wrap® is the choice for those who prioritize maximum lightness, quick drying, and compactness. Both share the same Finetrack DNA, but each shines in different conditions and activities.

Pocketable size to fit anywhere in your pack.

Equipped with the newly developed ultra-thin Everbreath® μ (Mu) membrane, the Mu Wrap®, weighing only 140g, is our lightest Mid Shell® to date. Its quick-drying, highly breathable performance makes it an excellent choice for year-round mountaineering and high-output activities. Lightweight and compact, it also works perfectly as a backup layer in your pack, ready to protect you from light rain or snow.