The Kamina Dome is a full-spec, four-season alpine tent. It delivers high structural strength, long-term durability, and a generous, stress-free interior space, while achieving exceptional compactness and top-tier lightweight performance.

That balance starts at the yarn level.

In this first installment, we take a closer look at the fly fabric, specifically, how a 15-denier base fabric can achieve serious strength through advanced yarn selection and precision weaving. Let's dive into it!

.png?sw=768)

The Foundation: 15D Ripstop 66 Nylon

Engineered from the Yarn Up

The fly fabric uses 15-denier yarns in both warp and weft, an extremely fine specification.

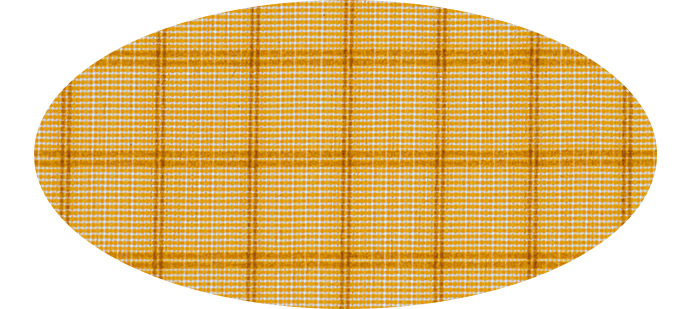

To prevent tearing, 40-denier reinforcement yarns are inserted in a grid pattern in both directions, forming a true bi-directional ripstop. All yarns are carefully selected and produced in Japan.

Denier measures the weight in grams of 9,000 meters of yarn. A 15D yarn weighs just 15 grams over that length. It is remarkably light.

The polymer is high-tenacity Nylon 66, chosen for its superior tensile strength, abrasion resistance, and structural stability compared to standard nylon. This allows the fabric to remain durable without increasing weight.

Why Density Matters More Than Denier

Denier alone does not define performance.

Two fabrics labeled 15D can behave very differently depending on weave density and reinforcement layout. The Kamina Dome fly is woven at high density, creating a tightly packed structure that improves tear resistance and coating stability.

Integrating thicker reinforcement yarns into such a fine, high-density base fabric is technically demanding. Inserting equal reinforcement in both warp and weft ensures balanced strength across the fabric plane, a rare capability achieved by only a handful of advanced mills in Japan, among the most specialized in the world.

Under magnification, fine yarns run in disciplined formation, intersected by thicker grid yarns that distribute load.

This is strength engineered into micro-architecture..

Strength-to-Weight, Without Compromise

The result is a high-density 15D nylon ripstop engineered to maximize performance per gram. It delivers excellent tear resistance relative to its weight, strong abrasion durability for its class, structural stability under alpine wind, and elite packability.

For a true four-season mountain tent, every gram must justify itself. That philosophy drives the Kamina Dome. By refining the invisible details, from fiber selection to reinforcement architecture, we achieve durability, stability, and remarkable lightness in one system.