For the 2025 Fall/Winter season, Finetrack is adding a new Mid Shell® to the L4 lineup: the Mu Wrap®. It represents a pursuit of ultimate lightness and packability, made possible by the expertise and dedication of Japanese textile makers.

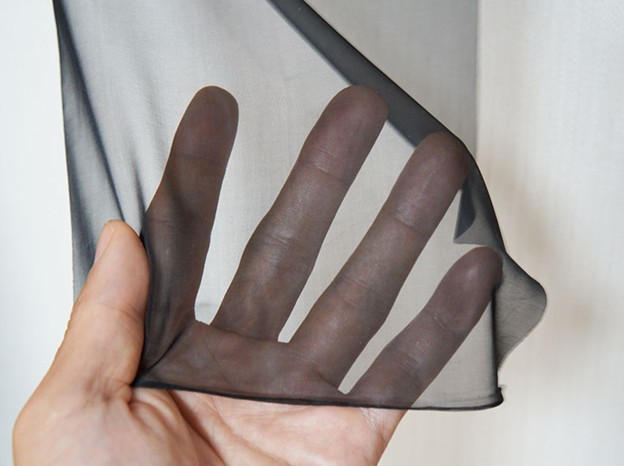

The project began with the discovery of a single waterproof-breathable membrane. From there, the team worked with domestic partners to develop a fabric so thin it is almost translucent, yet strong and functional enough for serious mountain use. This is the story behind the development.

Chasing the Limits of Thinness

The Mu Wrap® was born as an ultra-light, compact Mid Shell®, built with a newly developed fabric called Everbreath® μ (Mu). This three-layer material sandwiches a waterproof-breathable membrane between an outer and inner knit, achieving remarkable thinness, stretch, and quick-drying performance.

The project began with a breakthrough membrane developed by OG Film Co., based in Kanagawa, Japan.

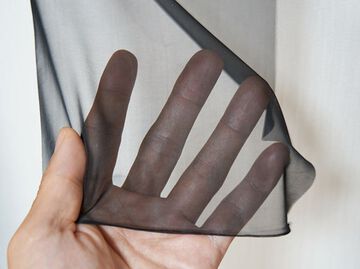

Non-porous membrane used in Mu Wrap®

Waterproof-breathable membranes generally fall into two categories: microporous and non-porous.

Microporous membranes let water vapor escape through countless microscopic holes while blocking liquid water. They provide excellent breathability but require a certain thickness to maintain durability. Our Everbreath® Photon uses this method.

By contrast, the polyester-based non-porous membrane used in Mu Wrap® has no holes at all. It absorbs moisture vapor and releases it outside. Traditional non-porous membranes made from polyurethane have a weakness: once they absorb water, they swell, dry slowly, and lose breathability, making them less effective in real-world use.

The polyester-based non-porous membrane developed by OG Film was different. It was incredibly thin, just one-third the thickness of the membrane used in Photon, yet it released absorbed moisture quickly, delivering outstanding breathability.

Everbreath® μ (Mu) Membrane

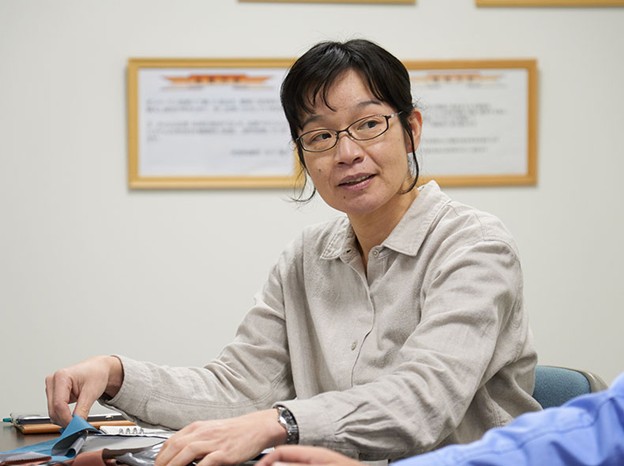

Tanaka, the Finetrack developer behind Mu Wrap®, recalls her first impression of the ultra-thin membrane from OG Film:

“It was unlike the typical polyurethane membranes I had seen before. The material was unique, and its thinness was unlike anything else on the market. I immediately thought, with this, we could create a garment that combines both thinness and comfort.”

Still, the membrane alone wasn’t enough to realize the lightweight garment she envisioned. To make it work, the team also needed an outer and inner fabric just as thin, and the technical skill to laminate all three layers into one functional material.

Tanaka, Finetrack Textile Development Team

Turning Vision into Fabric

To create an ultra-thin waterproof-breathable fabric, Finetrack partnered with Teijin Frontier, a Japanese textile maker with deep expertise in lightweight, high-performance materials. They had long collaborated with Finetrack, but this project pushed their skills further than ever.

From the start, the team knew the fabric would be used for L4 (Mid Shell®). Developer Tanaka explains:

“In our layering system, L4 is always worn under an L5 outer shell. That means the lighter we can make it, the more comfortable it becomes. So for this project, lightweight and compactness were our top priorities.”

The first step was choosing the right yarns. Ultra-fine polyester kept snapping in the knitting machines, making production impossible. Nylon was stronger, but it could not be dyed cleanly. After many trials, the best balance was found: a 15-denier polyester for the outer layer and an even finer 7-denier nylon for the inner layer.

At first glance, 15-denier polyester may not sound unusual, but the challenge was that we insisted on a knit construction.

Woven fabrics are stronger but less breathable and stretchy, while knits are softer and more elastic but typically weaker. In mountain use, durability often wins over stretch, but we believed comfort and stretch were equally essential. Choosing knits for both layers, while keeping the fabric thin and strong, was what made this project so demanding.

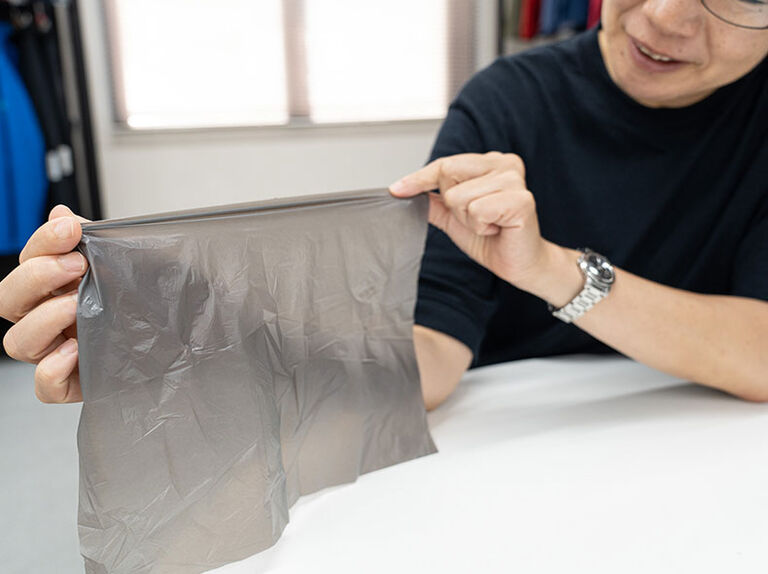

Feather-light outer fabric, laminated to the membrane with precision

Dyeing added another layer of complexity. As Teijin Frontier’s Mayu Nishimura recalls:

“Wovens can be dyed with roller machines, but knits stretch under tension, causing uneven colors. We had to use a liquid-flow dyeing machine, where the fabric floats in dye. Even the smallest snag could tear it. We had to manage flow speed and temperature with extreme care.”

Finally, once dyed, the outer knit, inner knit, and OG Film’s ultra-thin membrane had to be laminated into a single fabric. Even with advanced machines, this required skilled technicians to adjust tension by hand and ensure balance.

In the end, the collaboration between Finetrack and Teijin Frontier pushed Japanese craftsmanship to the limit, creating a fabric that is light, soft, stretchable, and durable enough for the mountains.

Mayu Nishimura, Teijin Frontier

Made Possible with Proud Japanese Craftsmanship

Most fabrics take a year or two to develop, but Everbreath® μ took nearly five years from concept to mass production. Looking back, Teijin Frontier’s Mayu Nishimura reflects:

“When we think about the time and effort that went into it, it’s deeply moving. Developing a knit fabric this thin was extremely challenging. Dyeing, laminating—everything required a level of skill that would be very difficult overseas. Without the cooperation and craftsmanship of Japanese factories, it simply couldn’t have been done.”

Even for OG Film, who created the polyester-based non-porous membrane, the final fabric went beyond expectations. Fuminobu Taniguchi recalls:

“We knew it would be thin, but not this thin. Seeing it made into a wearable garment was a real surprise.”

When you put on the Mu Wrap®, you’re wearing more than just an ultra-thin Mid Shell®. It carries the result of years of passion, persistence, and the expertise of countless engineers and craftspeople who brought it to life.

Fuminobu Taniguchi, OG Film Co.

Equipped with the newly developed ultra-thin Everbreath® μ (Mu) membrane, the Mu Wrap®, weighing only 140g, is our lightest Mid Shell® to date. Its quick-drying, highly breathable performance makes it an excellent choice for year-round mountaineering and high-output activities. Lightweight and compact, it also works perfectly as a backup layer in your pack, ready to protect you from light rain or snow.